Applications Manager

May 20, 2015

Introduction

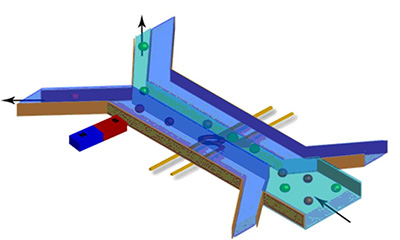

Biologists and chemists have developed miniaturized devices/systems that allow precise chemical control of reactions using only tiny amounts of material and cells. These devices are often formed using lithography techniques developed for the integrated circuit industry.

A series of masks are created and these allow exposure and subsequent etching at very fine geometries forming channels, valves, reaction chambers -- all on the order of a few microns in width.

The CAD or layout software used to create the various components of the fluidic device is often a mechanical drawing program such as AutoCAD. These drawing tools are very flexible and include programming languages that enable parametric generation of complex shapes and patterns.

However the drafting tool was not intended for mask data and enables (or allows) the user to produce layouts that will not produce the desired mask results.

This article describes the mask making data process along with some specific drawing directives that will insure that what you intend is what you get when the mask is produced.

Even if you are not using masks but some other process (such as direct write or laser cutting, milling or 3D printing) the directives provided still apply.

The AutoCAD Database DWG/DXF

AutoCAD is one of the most popular and commonly available software for precison drafting. We'll refer to it from now on even though there are many other tools available, they almost all produce AutoCAD's DXF format and that is what will be used to fabricate your mask.

Pros and Cons of AutoCAD

AutoCAD's biggest pro is the flexibility it gives the designer. Unfortunately, this is also AutoCAD's biggest con. Why?

Drawing in AutoCAD is problematic because the database will need to be converted into something that drives either a cutting machine or a mask making machine. And these machines depend on very clear understanding of what is to be kept and what is to be discarded. Unfortunately, when using AutoCAD lines and arcs such an understanding is not always obvious.

Best Practices

What we will discuss in the next few pages are some best drawing practices that will result in correct conversion and mask output.